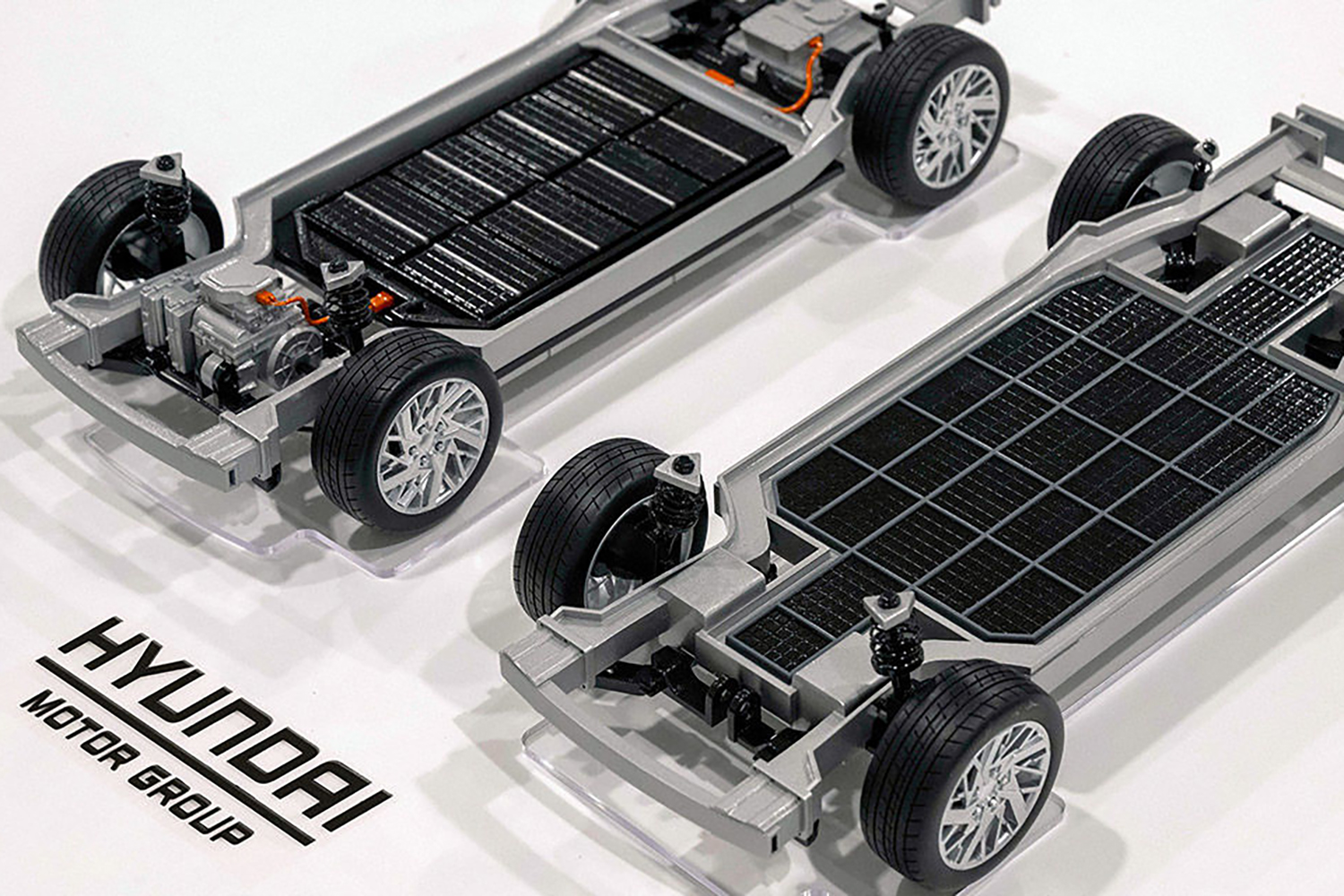

Electric vehicles already offer vehicle designers much more opportunity to expand interior room; their batteries are mounted flat on the floor, and the motors take up much less space than a conventional internal combustion engine. But engineers at Hyundai and Kia have come up with a solution to make the drivetrain packaging even smaller: basically, putting the transmissions and CV (constant velocity) joint inside the wheel.

The Universal Wheel Drive System, or ‘Uni Wheel,’ would use at least two – if not four – electric drive motors, mounted firmly to the chassis at each wheel. Instead of a flexible CV joint connecting the motor to the wheel, it’s a stationary drive shaft. And here is where it gets interesting.

As you’ll see in this video, the engineers put the reduction gears that are normally found on the motor inside the wheel. And they made them with a flexible arrangement – using a set of sun, planetary and ring gears, like what you’d find in a conventional transmission, but on moveable levers – to absorb the up-and-down movement of the wheel that would normally be absorbed by the CV joint. And because the motor doesn’t need an attached transmission, it would take up less space on the chassis.

Hyundai/Kia’s new UniWheel design

Apparently, it took them a while to figure out the best possible arrangement, but the result is a startling increase in free area that can be used for more cabin interior space. And this technology isn’t just meant for cars, either; it can be used in a variety of mobile transportation, such as bicycles, wheelchairs and even robots, and the Uni Wheel can be used for climbing stairs.

It’s still in the testing stage, but the company has filed for eight patents globally. Hopefully, we’ll see this arrangement – and the different design possibilities that come with it – soon.