With a Level 3 charger, the battery of a Ford Mustang Mach-E can top up to 80 per cent in about 30 minutes. We take that time to talk with Patrick Gervais, the vice-president of marketing and communications at Lion Electric, about his company’s past, the rosy future and the challenges and benefits of electrifying large fleets.

As decreed by the federal government, every new car sold in Canada will be fully electric by 2035. And with every automaker now either offering or developing EVs for the market, it looks like we’re well on our way to having an EV in nearly every driveway before then.

But lost in the hubris of sexy cars such as the Tesla Model 3 and Mercedes-Benz EQS is another segment of transportation that would benefit everyone by going electric, a segment that most people ignore. Tens of thousands of diesel-powered buses and delivery trucks travel Canadian roads every day, spewing greenhouse gas (GHG) emissions on short trips that end back at the same depot. It’s this segment that Lion Electric, an electric bus and truck builder based in Saint-Jérôme, QC, is working hard to change.

Patrick Gervais had previously owned an advertising company, and Lion Electric was his client. In 2018, he sold the company and joined Marc Bedard, the founder and CEO of Lion, and now Gervais talks with The Charge about the early days of the company, when it led the way in electrification in the segment.

“Mark wanted to reinvent, or change the world of transportation,” says Gervais. “So in 2008, he created Lion, which used to build diesel school buses. They had composite bodies, and they were the first school buses to use three-points seatbelts. They were lighter, they were saving on fuel, and they were safer for the kids.

“And then he said, ‘We can’t stop there, we have to go somewhere else.’ So they looked at all the propulsion that was available at that time; propane, everything. And then in 2010 they decided to go 100 per cent electric. Everyone thought he was crazy. Everyone seemed to think, this is will never happen.

“And then in 2016, after over five or six years of development, they put the first bus on the road, 100 per cent electric. The buses had about 100 kilometers of range at that time. And as of today, we have over 450 vehicles with more than 13 million kilometers driven.”

Rather than jump into the crowded and established world of electric cars, Bedard saw the opportunity in larger vehicles, such as buses and medium-sized delivery trucks – vehicles that have established routes and return to a home base every day, which is ideal for electric vehicles. And it’s a segment that’s among the worst in ground transportation for greenhouse gas (GHG) emissions.

“There are 13.5-something million heavy duty trucks in the United States,” says Gervais. “And then there’s about 1.5 million of them in Canada. And I think it’s 56,000 school buses in Canada. Imagine a truck, it’s about 75 to 100 tonnes in terms of GHG emission; a school bus, it’s 20 to 23 tonnes. So if you add that up, the amount of GHG emissions that will be saved, that’s amazing, that’s for the environment.

“School buses were a perfect vehicle to go electric because it always does the same route with a small amount of kilometers. They do a route in the morning, you can charge during lunchtime, and then do another route in the afternoon.”

In 2018, the company launched its first Class-8 truck, then moved on to two different school buses, a minibus, and four more truck sizes. They also make garbage trucks and, this year, will begin producing an all-electric ambulance and other products.

Read more: Lion Electric, Demers unveil EV ambulance of the future

Of course, just like the auto world, electric buses and trucks are more expensive than their diesel-powered counterparts, which could be a deciding factor for cash-strapped fleet services. But Lion Electric works hard to show that, in the long run, EVs will save fleets money.

“Today, [EVs] are about two to three times more expensive,” admits Gervais, “but you will save 80 per cent on energy cost. And then you will save over 60 per cent in maintenance. So when you look at the total cost of ownership, electric will always be cheaper than a combustion engine.

“We always say, the more you roll, the more you save. When you put on 5,000 kilometers a year or more, it takes three to five years, then you’re back into your money [with the savings in fuel and maintenance].

A class-6 EV truck from Lion Electric

“As time goes by, we feel that within five years from now, the latest electric vehicles will be the same prices as combustion engine vehicles, with the advancement and development of technologies. No one expected electrification technology to move as fast as it has.”

The company has learned a few things itself along the way. Selling electric vehicles to fleets that have always used diesel combustion engines can’t just end when you hand over the keys.

“We’ve put a whole ecosystem together to make sure that you identify the situation where the vehicle is operating. So that’s the first thing, second thing is to look at the right vehicle. Third thing is, you need to look at charging infrastructure. So we have a team dedicated to the whole ecosystem that we’ve put together to make sure that transition towards electric is being done correctly and smoothly.”

That team also includes people to train drivers and mechanics, as well as a partnership with Geotab, another Canadian company, for continued logistics and monitoring.

“There’s a little bit of change and new stakeholders and new ways of doing things,” says Gervais. “You need to make sure that people are comfortable and aware of how it’s being done.”

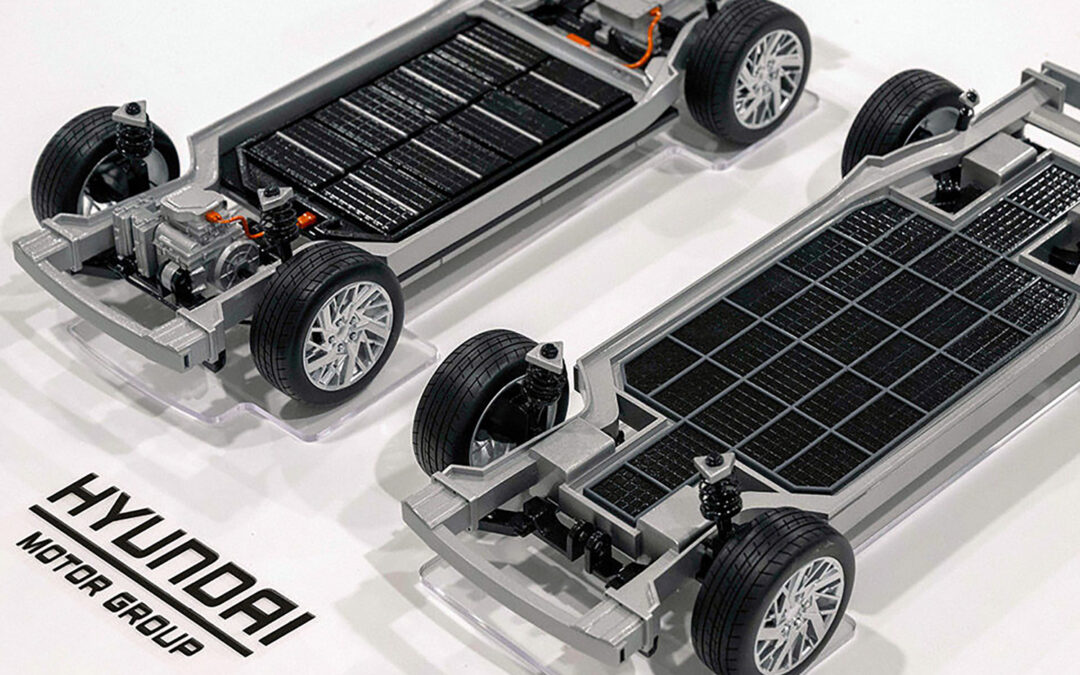

Lion Electric’s upcoming battery plant in Mirabel, QC

This year is going to be a big one for Lion Electric. Not only do they have more vehicles planned, but they also have a new factory in Joliet, Illinois, coming online in the second half of the year that the company says will be the largest dedicated production site for zero-emission medium- and heavy-duty vehicles in the US, with an annual production capacity of up to 20,000 vehicles. They are also building a $185 million battery plant and innovation centre in Mirabel, QC, very near its current headquarters and assembly plant in Saint-Jérôme. Gervais is optimistic about the company’s future, to say the least.

“We have a purchase order book of 2,024 vehicles as of today. And we already have 450 vehicles on the road,” he says. “We’re really excited about this. We’re proud of this, too.

“Our objective is to put as many vehicles that we can on the road, as soon as possible.”