Production of Audi’s new Q8 e-tron has officially begun at the German brand’s ‘Factory of the Future’ facility in Brussels.

The Q8 e-tron was officially revealed last month as the renamed replacement for the all-electric e-tron, Audi’s flagship electric model since its arrival in 2018. Around 160,000 examples of the e-tron have been produced since then.

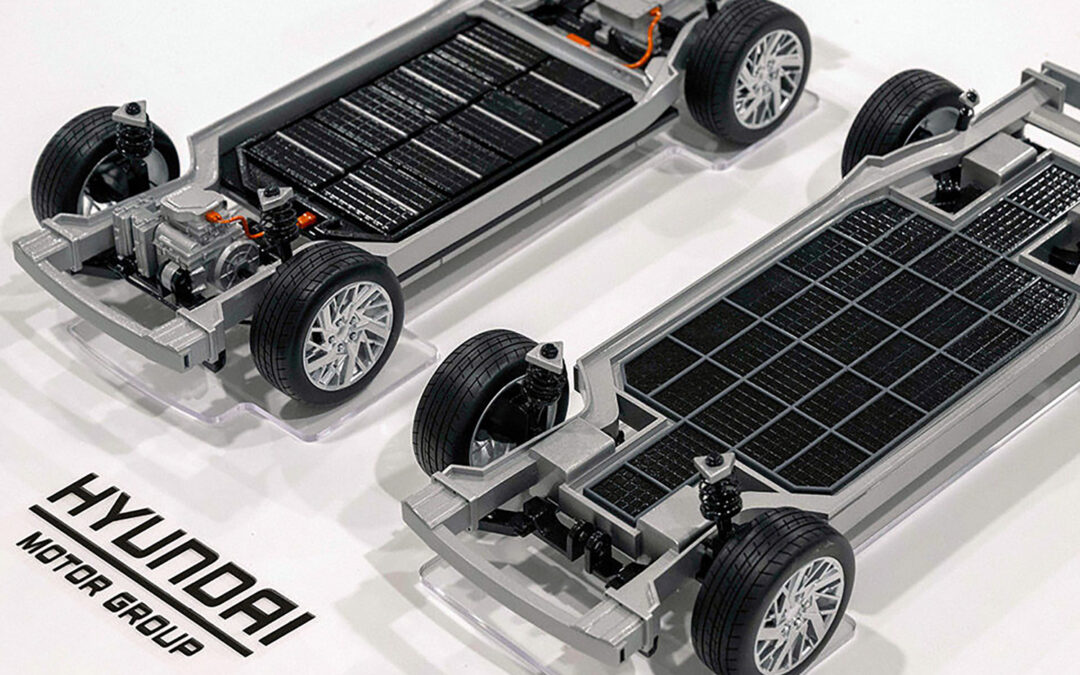

In Brussels, the chassis, transmission, e-motor, and high-voltage battery are installed in the body of the Audi Q8 e-tron.

Despite the new nomenclature, the Q8 e-tron retains both its SUV and more rakish Sportback forms, both of which are powered by dual electric motors. The entry level ’50 e-tron Quattro’ of both models features an 89 kWh battery and features an output of 335 hp and 490 lb-ft of torque. This increases to 402 hp for both in the mid-range ’55 e-tron’ examples – torque remains unchanged, though a larger capacity 106 kWh is fitted – and 496 hp and 718 lb-ft of torque for the range-topping SQ8 e-trons, the latter of which is powered by three e-motors. The larger kWh battery pack also increases estimated electric range up to 582 km in SUV form and up to 600 km for the Sportback.

Read more: Audi introduces Q8 e-tron with more range

Interestingly though, while the first example of the Q8 e-tron to roll off the line marks an important new era for Audi’s EV range, focus instead is on the sustainable nature of production at its Brussels plant.

All components on the line are ready for the “wedding”.

Built for customers in Europe and across North America, the new Q8 e-tron is said to be a “certified net carbon-neutral” model as part of the Brussels’ plant’s ‘’Factory of the Future’ moniker. In keeping with Audi’s ‘Mission:Zero’ program, the Belgian plant switched to green energy in 2012 by installing 107,000 sq m of photovoltaic (née solar) systems on-site, enough to generate around 9,000-megawatt hours of power each year and theoretically eliminate up to 1,881 tons of carbon emissions.

Suppliers for Audi’s battery assembly facility, also based in Brussel, are “obliged” to use renewable energy sources during production, with even a rail transport network – established in May of this year – between the supplier in Hungary and the plant in Belgium said to reduce carbon emissions by 2,600 tons annually over conventional road-going freight.

Production at all Audi facilities is set to follow suit and be carbon neutral by 2025.