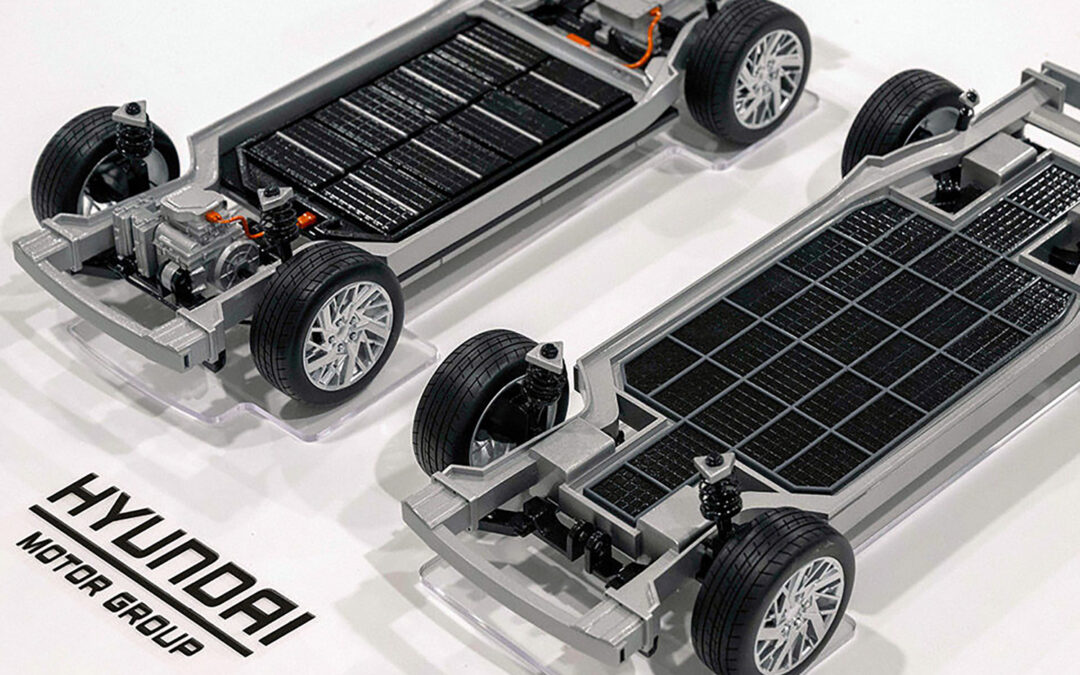

Volkswagen unveiled plans for its largest battery plant to-date in St Thomas, Ontario, with production set to begin 2027.

The Gigafactory, the first overseas battery facility for both the Volkswagen Group and its battery subsidiary PowerCo SE, marks a key step in VW’s plans for EV expansion in North America, which includes the introduction of “the broadest portfolio” of full EVs in both the US and Canada by 2030. The Group’s revived ‘Scout’ brand will start introducing US-targeted electric off-roaders from 2026 onwards.

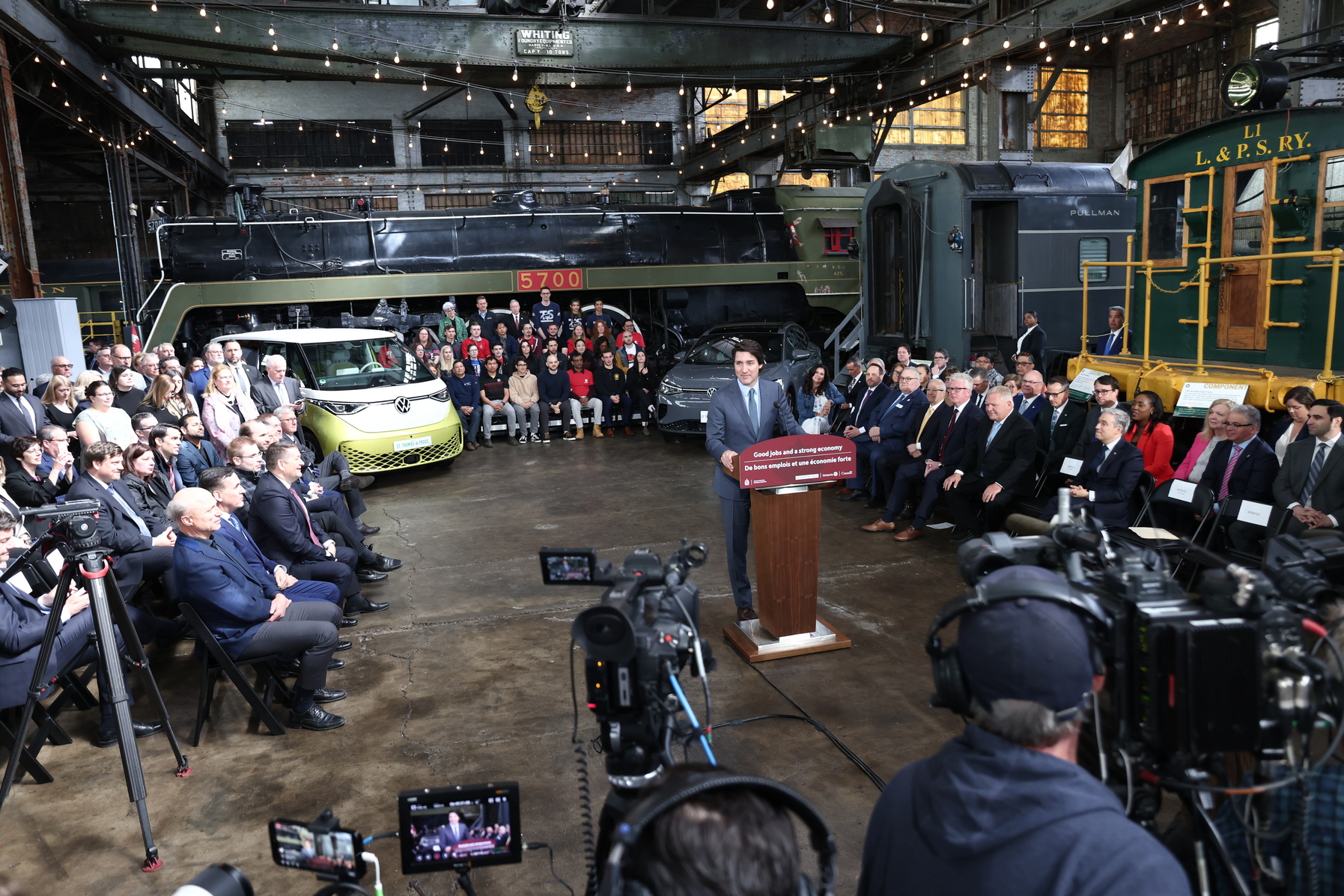

Justin Trudeau, Prime Minister of Canada, at the announcement of further details of the future battery cell factory in front of citizens of St. Thomas and other guests.

To achieve its target, the German automaker is investing more than $7.1 billion into the site across the next seven years. The federal government will give up to $13 billion in subsidies over the next 10 years, while the Ontario provincial government will add $500 million in ‘direct incentives’.

The new battery facility – an “important milestone” – is on course to be the largest manufacturing facility in the country, once built, and the largest cell factory to date for VW.

“North America plays a key role in our global battery strategy,” VW Group board member Thomas Schmall explained in an official statement. “The region will become PowerCo SE’s second pillar beside Europe, with battery cells made in North America for North America.

“Gigafactory St. Thomas opens the door to a key market for e-mobility and battery cell production. We aim to make PowerCo a global player in the battery business and to pave the way for clean, sustainable mobility. Gigafactory St. Thomas is an important milestone in our roadmap.”

The cell factory itself will cover around 370 acres – or 210 soccer fields – just 30 km south of London, a “strategic location” that provides access to major hubs and supply chains in Toronto and Detroit. Interestingly, though no further details were provided, the “entire industrial and supplier park” associated with the battery plant will cover closer to 1,500 acres.

Ground-breaking is scheduled to begin in 2024, with VW hoping the endeavor will create up to 3,000 new jobs. Six production lines will be in-place to make enough batteries for up to one million EVs and, eventually, meet annual production targets of up to 90 gigawatt hours per year.